ABOUT

As the number of end-of-life (EoL) lithium-ion batteries (LiB) continues to grow, particularly low-value types like lithium iron phosphate (LFP), recycling becomes a major challenge. Existing technologies are not yet efficient or cost-effective enough to handle them.

ReUse aims to develop innovative, sustainable, and energy-efficient processes for the direct recycling of LFP-based LiBs and their production waste.

The project focuses on scalable solutions with high recovery efficiency and purity, supporting compliance with the EU's new Batteries Regulation.

ReUse is a research initiative co-funded by European Union and the State Secretariat for Education, Research, and Innovation (SERI). It is part of the Battery 2030+ Partnership launched under Horizon Europe.

OBJECTIVES

Develop automated EoL-battery sorting and optimized discharge schemes.

Develop automated disassembly/deconstruction strategies for LFP battery cells.

Improve recycling efficiency and direct re-use of battery active materials, conductive carbon, and binders through improved separation and regeneration methods.

Ensure sustainability of the ReUse concept by LCA, LCC, and Social Impact studies.

CONCEPT

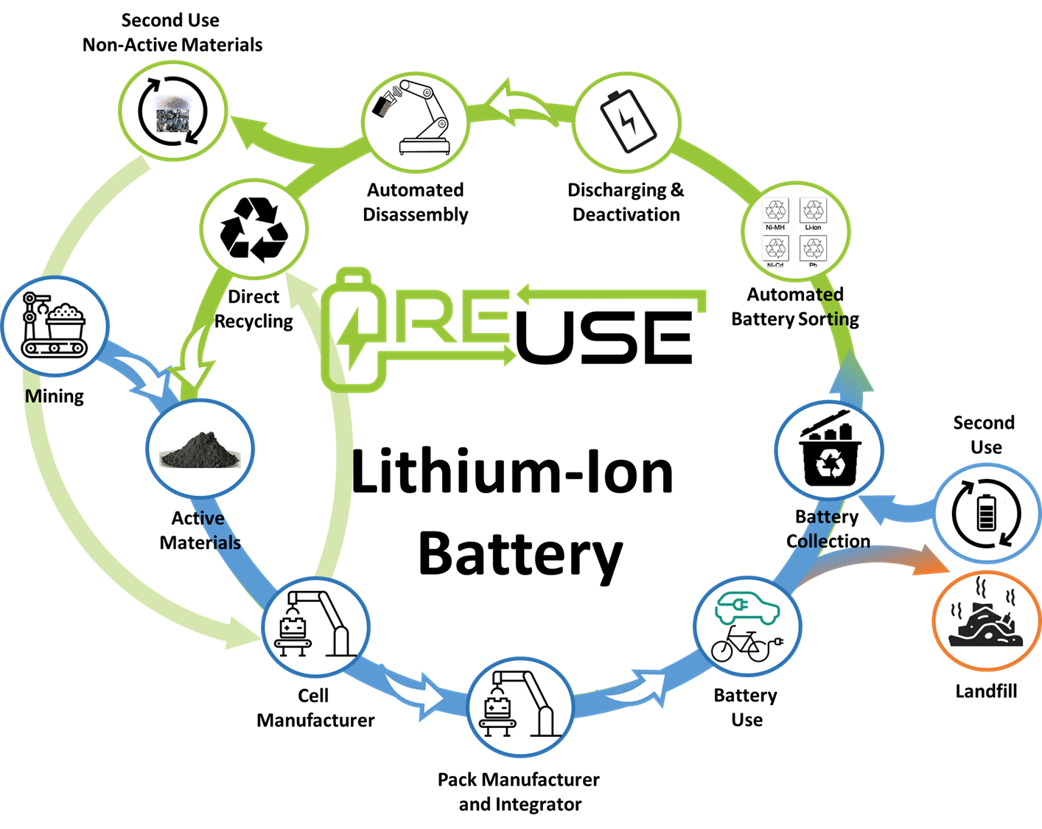

ReUse develops a circular process to recover, purify, and regenerate materials from EoL LFP batteries, enabling their reuse in new battery production while minimizing environmental impact.

To enable direct recycling, pure materials need to be recovered from battery waste, for which ReUse will apply automated sorting according to battery chemistry, deactivation of lithium-ion batteries, and automated cell disassembly.

The contribution of the project ReUse in the battery value chain is shown with green arrows.

Learn more by clicking on each process

Discharging & Deactivation

This step involves safely discharging batteries and deactivating them, while preserving material quality in preparation for further processing.

Automated Disassembly

Battery components are separated, cleaned, and prepared for further processing in controlled environments with minimal emissions.

Second Use of Non-Active Materials

Non-active materials are purified and reused, enhancing circularity and resource efficiency.

Direct Recycling

Advanced techniques regenerate cathode and anode materials to battery-grade quality, enabling their reuse in new battery production.

Automated Battery Sorting

AI-based sorting technology identifies and separates EoL LFP batteries from mixed waste streams.

Battery 2030+ Contribution to the Battery Value Chain

These processes are led by the Battery 2030+ initiative, which closely collaborates with ReUse to achieve shared goals in battery research and development.

EOL Battery Preparation

1

Batteries are sorted using AI-driven systems, safely discharged, and deactivated to prepare for processing. Ensures safe handling and realistic feed materials for recycling processes.

SORTING

AI-based sorting technology identifies and separates EoL LFP batteries from mixed waste streams.

Pilot plant at SORTBAT (Belgium) demonstrates a capacity of 1-2 tons/hour.

DISCHARGING

Develops universal methods to safely discharge batteries while preserving material quality.

Investigate the effects of discharge parameters (voltage, temperature, etc.) on material recovery.

DEACTIVATION

Innovative techniques involving protective atmosphere systems and subsequent perforation and/or shredding of charged LFP cells.

Prepares a safe, high-quality feedstock of EoL batteries for subsequent processing steps.

Automated Disassembly and Material Separation

2

Automated disassembly in controlled environments separates battery components (cathode, anode, and casing). Materials are cleaned and prepared for further processing with minimal emissions.

AUTOMATED DISASSEMBLY

Cells are opened, and components (cathode, anode, casing) are extracted in a controlled environment.

Techniques like laser cutting, milling, and automated handling ensure precision.

SHREDDING AND DELAMINATION

New and improved shredding configurations enabling more selective material recovery.

MATERIAL RECOVERY

Components are cleaned of residues like electrolyte salts and binders, preparing them for purification.

Provides separated and clean battery materials while ensuring safety and environmental compliance.

Extraction and Purification

3

Recovered materials like lithium salts and binders are purified using solvent extraction and centrifugation. Water and valuable materials are reclaimed for reuse, enhancing circularity.

ELECTROLYTE RECOVERY

Solvent extraction and vacuum distillation reclaim valuable components like LiPF.

BINDER REMOVAL

Techniques such as Soxhlet extraction and ultrasonication separate binder materials from active components.

BLACK MASS CLASSIFICATION

Centrifugation separates active cathode materials and carbon black for reuse.

WASTEWATER

Wastewater from processes is purified to recover dissolved metals and enable water reuse.

Ensures high-purity recovery of critical materials and maximises resource efficiency.

Regeneration

4

Cathode and anode materials are regenerated using advanced techniques such as microwave-assisted synthesis and re-graphitisation. Ensures recovered materials meet the quality standards for new batteries.

CATHODE MATERIAL REGENERATION

Uses microwave-assisted hydrothermal and dry annealing methods to restore spent LFP cathode material for re-use in new batteries.

Electrochemical regeneration introduces lithium to achieve the desired material quality.

ANODE MATERIAL REGENERATION

Hybrid processes, including washing and thermal treatment, remove impurities and restore graphite for reuse.

PROCESS OPTIMIZATION

Focuses on minimising energy use and adapting methods to handle impurities in recovered materials.

Restores battery-grade materials for new production, closing the recycling loop.

CONSORTIUM

The ReUse project brings together 13 partners from 8 countries:

Germany, Belgium, Norway, Czechia, France, Denmark, Switzerland and Serbia.